Activity 7. Case study, in core fuel management

Activity 7. Case study, in core fuel management

Objectives:

- Apply a case study about in-core fuel management.

Student work:

- Individual

Product:

- Solved Case study

Resources:

- Questionnaire

Instructions:

Student

- Read the case study situation carefully.

In a text document, incorporate the solution to the following case: - As the engineer responsible for fuel management at the nuclear power plant, you must specify to the fuel supplier the characteristics of the reactor's equilibrium cycle, which must begin within two and a half years.

- Uranium (U3O8 ): $142.66/ kgU

- Conversion to UF6: $40.25/kgU

- Enrichment: $134/kgSWU

- Fabrication: $151.75/kgUenr

- Storage: $93/kgHM

- Final (geological) disposal: 540 $/kgHM

- De-conversion of depleted uranium: $6/kgDU

- Disposal of depleted uranium: $9/kgDU

- Upload the file with your answers in this space, naming the file as follows: LastNameFirstName_CaseStudyIn-core (example: DominguezEsteban_CaseStudyIn-core).

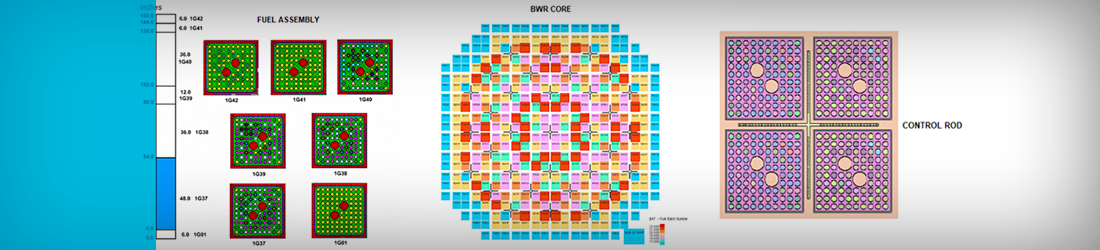

The reactor is a BWR-SMR of 870 MWth of thermal power, a thermal efficiency = 34%, with a core of 240 fuel assemblies, with a reload fraction n = 4, and an operation cycle length L = 2 years (730 EFPD ).

First, you will need to calculate the average enrichment of the fuel batch. Next, you will estimate the discharge burnup of the fuel batch and the uranium consumption per electric power generated, knowing that the enrichment plant operates with tails of 0.2%.

Once you have calculated the required average fuel enrichment, you ask the fuel supplier to design the fuel assembly according to your requirements and within the production line they run for the BWR-SMR.

The supplier gives you the design report of the fuel assembly, however, you want to verify one of the proposed lattices, since you consider that it is possible to improve it. To do this, you evaluate three designs: option three being that of the fuel supplier. Which turns out to be the best?

In order to evaluate the lattices, you have the following information obtained from evaluating them with your lattice design system, which uses the scatter search metaheuristic technique:

Enrichment:

|

E1 = |

4.5 % |

|

E2 = |

4.5 % |

|

E3 = |

4.5 % |

Effective neutron multiplication factor, k:

|

Quemado (MWd/t) |

0 |

50 |

1000 |

12000 |

15000 |

20000 |

|

k-reference |

1.02929 |

1.0087 |

1.01129 |

1.13167 |

1.14318 |

1.11704 |

|

k1 |

1.03013 |

1.01255 |

1.01515 |

1.13167 |

1.13883 |

1.11279 |

|

k2 |

1.03161 |

1.01255 |

1.01515 |

1.13599 |

1.13883 |

1.11279 |

|

k3 |

1.02975 |

1.01642 |

1.01903 |

1.12737 |

1.13450 |

1.10856 |

Gadolinia:

|

Gd ref = |

0.8152 |

|

Gdo1 = |

0.8152 |

|

Gdo2 = |

0.8043 |

|

Gdo3 = |

0.7931 |

Power peaking factor:

|

PPFmax= |

1.45 |

|

PPFo1 = |

1.4 |

|

PPFo2 = |

1.44 |

|

PPFo3 = |

1.514 |

Weighting factors:

|

WE = |

1 |

|

Ws = |

10000 |

|

WG = |

100 |

|

Wp = |

50 |

Once the design of the fuel assembly has been agreed with the supplier, to ensure that it is less than 3.15 you need to evaluate the total peak power factor (TPF), knowing that the fuel assembly produces 15% more power than the average power of all the assemblies in the core. Furthermore, axially the highest power node produces 40% more than the average power of all nodes in the assembly, and the highest power pin of that node produces 35% more than the average of all pins. Other than the TPF, what is the power, in MWth, of the highest power pin? And, to make sure that it is greater than 1.3, you must also evaluate the critical power ratio (CPR) of this assembly, knowing that the critical power is 5.8 MWth.

Now, it is required to evaluate the performance of the core in the equilibrium cycle with the reload of the proposed fuel batch. To do this, you have the following information that you obtained from your reload pattern design system that uses the tabu search metaheuristic technique. Determine which is the best of the three proposed designs:

Cycle length:

|

Energy1= |

12581 MWd/t |

|

Energy2= |

12375 MWd/t |

|

Energy3= |

12469 MWd/t |

Power peaking factor:

|

PPF1 = |

1.75 |

|

PPF2 = |

1.53 |

|

PPF3 = |

1.54 |

Maximum lineal heat generation rate:

|

MLHGR1= |

371 W/cm |

|

MLHGR2= |

373 W/cm |

|

MLHGR3= |

380 W/cm |

Fraction of the limiting average lineal generation rate:

|

XMPGR1= |

0.84 |

|

XMPGR2= |

0.82 |

|

XMPGR3= |

0.83 |

Maximum relative nodal power:

|

MRNP1 = |

2.38 |

|

MRNP2 = |

2.23 |

|

MRNP3 = |

2.24 |

Maximum fuel assembly burnup:

|

MFAB1 = |

54 GWd/t |

|

MFAB2 = |

54 GWd/t |

|

MFAB3 = |

56 GWd/t |

Shutdown margin at beginning of cycle:

|

ΔSDM1 = |

1.2 %Δk/k |

|

ΔSDM2 = |

1.1 %Δk/k |

|

ΔSDM3 = |

1.3 %Δk/k |

Effective neutron multiplication factor:

|

Kef crit = |

1.00000 |

|

Kef1 = |

1.01700 |

|

Kef2 = |

1.01900 |

|

Kef3 = |

1.02100 |

Weighting factors:

|

W1 = |

1 |

|

W2 = |

1000 |

|

W3 = |

100 |

|

W4 = |

1000 |

|

W5 = |

1000 |

|

W6 = |

100 |

|

W7 = |

100 |

|

W8 = |

100 |

Furthermore, what kind of reload pattern design strategy would you propose to the reactor engineer, if you want to reduce neutron leakage (to reduce irradiation to the vessel), while also wanting to flatten the power distribution in the core?

Finally, the manager of the nuclear power plant asks you to calculate the levelized cost of the fuel cycle (with the breakdown of each of its stages), assuming a once-through (open) cycle and according to the following unit costs:

And, considering the lead and lag times recommended by the IAEA, a discount rate of 7%, and a discharge burnup guaranteed by the fuel supplier of 60,000 MWd/tU.

Teacher: Request the solution